In the world of electrical engineering and aerospace, reliability is essential. One critical component that ensures strength and performance under harsh conditions is the hermetic sealed connector. Designed to prevent the infiltration of moisture, dust, and other pollutants, these connectors play a important role in preserving the integrity of delicate electronic systems. Knowing how hermetic sealed connectors work can help engineers and designers make educated decisions when it comes to selecting the appropriate components for their assignments.

Hermetic sealing utilizes advanced manufacturing techniques to create a shield that protects internal wiring and circuitry. This approach not only improves the longevity of connectors but also maintains their functionality in harsh environments such as elevated humidity, extreme temperatures, and even low-pressure conditions. As we explore the science behind these advanced connectors, we will uncover the materials, configurations, and testing methods that contribute to their effectiveness and reliability, ensuring they meet the demands of modern technology.

Comprehending Airtight Closure

Airtight sealing is a technology designed to produce a totally airtight and humidity-resistant container, securing that vulnerable components are protected from environmental factors. The phrase "hermetic" comes from the name Hermes Trismegistus, an historical personage linked with the art of alchemy, capturing the concept of locking away vital parts. This technique is especially crucial in fields where electronic systems are vulnerable to severe circumstances, such as the aerospace sector, armed forces applications, and clinical instruments.

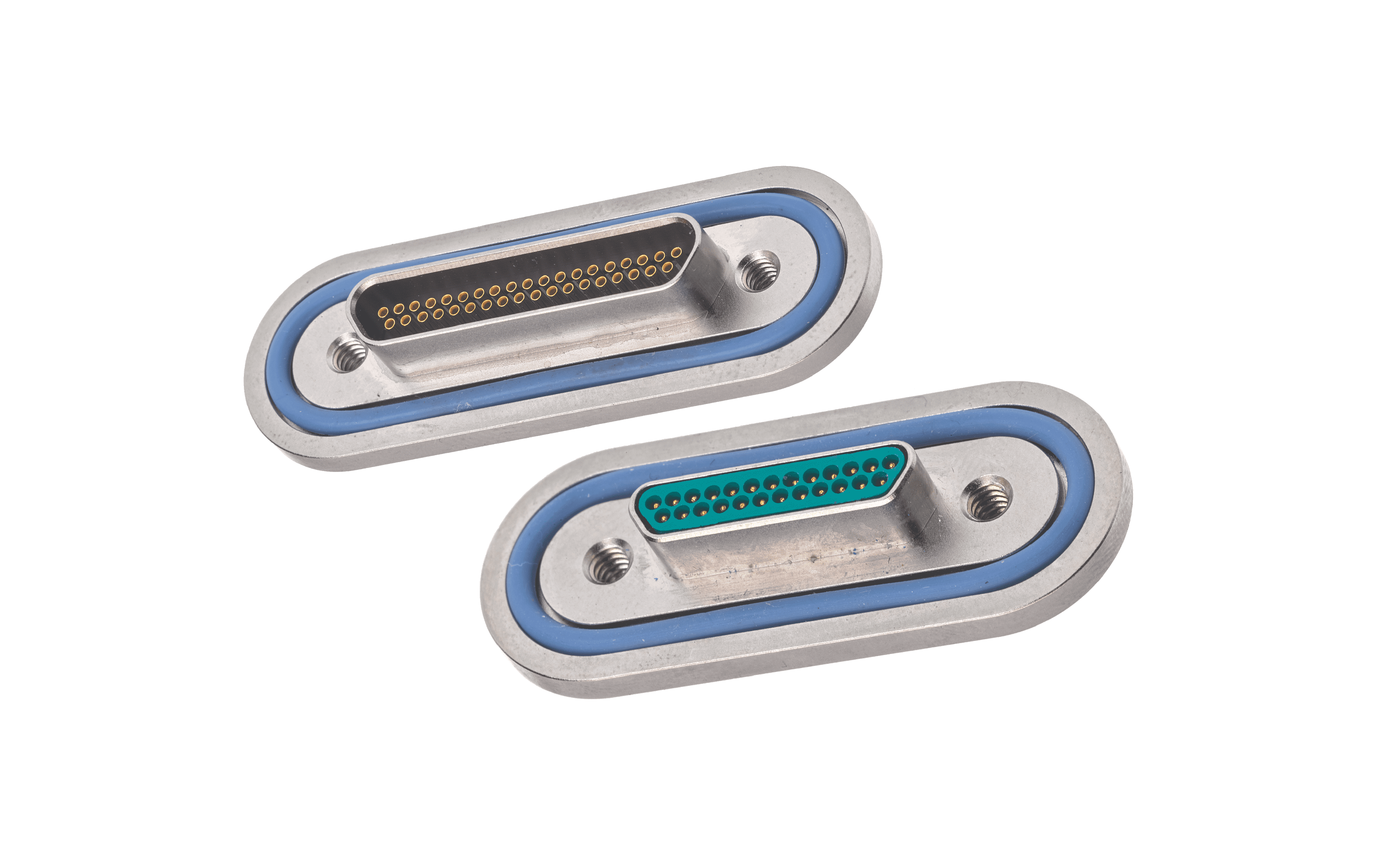

The primary function of a hermetic seal is to block the infiltration of gases, fluids, and contaminants that could jeopardize the efficiency and reliability of electronic interconnections. This is attained by using materials and methods that create a strong shield around the joint. Standard methods include bonding, glass and metal connections, and the use of custom gaskets that fit tightly within the case of the connector. These methods verify that the inside components are shielded from severe surroundings that could otherwise lead to breakdown.

In addition to shielding against pollutants, hermetic seals also help sustain the integrity of the internal environment, often facilitating the use of delicate instruments in low-pressure or controlled conditions. The efficacy of hermetic seals is measured in terms of leakage levels, which indicate the volume of air or moisture that can pass through the barrier over time. This measurement is vital, as even small leaks can lead to significant damage in sensitive contexts. As technology advances, innovations in hermetic sealing remain to evolve, offering superior robustness and dependability for modern interfaces.

Uses of Sealed Connectors

Closed connectors are essential in sectors where environmental conditions can jeopardize the integrity of electrical connections. In the aviation industry, for example, these connectors ensure reliable performance in high-altitude and high temperature conditions. By preventing moisture and pollutants out, hermetic connectors guarantee that delicate avionics systems perform properly, which is necessary for flight security and reliability.

In the medical field, hermetic connectors play a pivotal role in devices that must maintain hygiene and prevent contamination. They are used in numerous applications, including testing equipment and surgical tools, where contact to outside elements could risk patient safety. The effective sealing provided by these connectors helps ensure that devices operate accurately and dependably, even in the most delicate environments.

The telecommunications industry also gains from hermetic sealed connectors . These connectors are utilized in fiber optic systems and additional communication devices that require protection from dust, humidity, and chemicals. Their strong sealing capabilities enable long-term reliability and maximum performance, making them a favored choice for setups in extreme outdoor settings or environments prone to harmful substances.

Advantages of Sealed Connectors

Sealed sealed connectors provide substantial benefits in settings where moisture, dust, or other contaminants can profoundly impact the efficiency and consistency of electronic systems. Their ability to create a total barrier against gases and fluids ensures maximum protection for sensitive components. This makes them vital for purposes in aviation, defense, and healthcare devices where environmental extremes are frequent.

Another key advantage of tight connectors is their lifespan. These connectors are engineered to endure severe conditions without jeopardizing their integrity. The sealing materials and construction lessen wear and degradation over time, which leads to decreased maintenance costs and prolonged service life for the equipment they connect. This reliability is crucial for systems that are often challenging to access or costly to replace.

Furthermore, tight connectors help preserve signal integrity by providing stable electrical connections in challenging environments. The sealed nature of these connectors prevents oxidation and electrical failures that can occur in standard connectors exposed to humidity or hazardous exposure. This reliability in signal transmission is critical in mission-critical applications, ensuring that systems perform smoothly without unexpected downtime.